16 mai 2025

Refroidissement de cave à vin vitrée : les 5 erreurs à éviter pour un cellier silencieux et performant

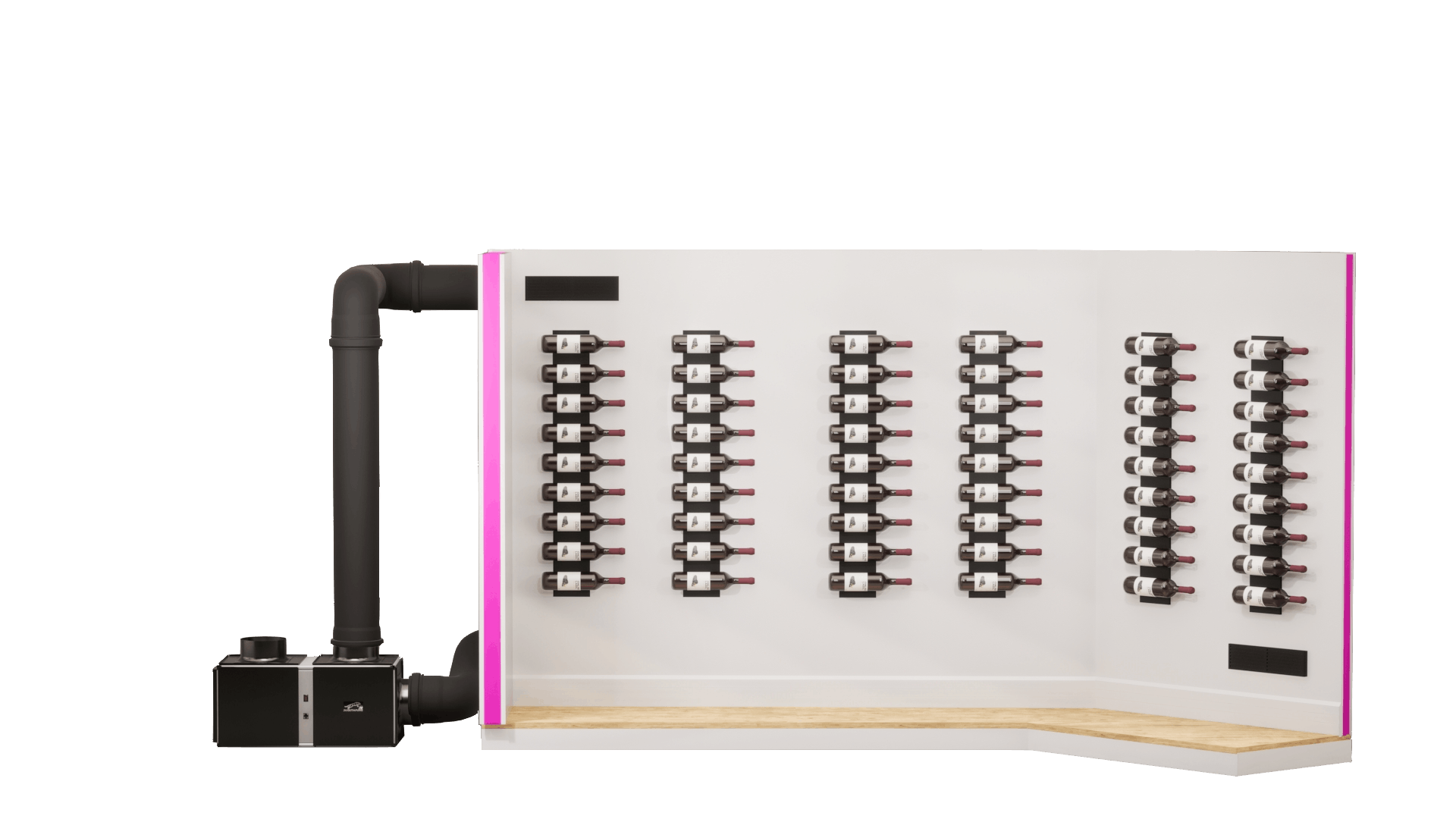

Installer ou concevoir un cellier en verre haut de gamme exige une expertise technique précise. Un système de refroidissement par conduits mal dimensionné ou une isolation insuffisante peuvent compromettre la conservation du vin et l’esthétique de l’installation. Découvrez comment les APEX 3500, 5000 et 7000 de Panthaire assurent un contrôle silencieux et précis de la température et de l’humidité, même dans les caves vitrées les plus exigeantes.

Introduction

Les caves à vin vitrées sont devenues un symbole de design et et de modernité. Cependant, le refroidissement d’un cellier en verre est bien plus complexe que celui d’une cave traditionnelle. Le verre a un facteur R nettement plus faible (~R-2) qu’un mur isolé (~R-20), ce qui augmente considérablement les charges thermiques. Sans une planification rigoureuse — isolation, pare-vapeur, dimensionnement BTU, et circulation d’air maîtrisée —, vos vins risquent de subir des variations de température et de l’humidité excessive.

Les systèmes APEX Panthaire, conçus et optimisés pour les celliers vitrés, intègrent :

- Un fonctionnement entièrement gainé (conduit d’alimentation d’air + conduit de retour d’air)

- Des ventilateurs ECM à vitesse variable

- Une gestion intégrée des condensats avec bac en acier inoxydable et module d’auto-évaporation

- Une puissance adaptée aux charges thermiques élevées des vitrages

1 – Isolation thermique insuffisante des parois vitrées

Problème :

Le vitrage standard laisse entrer la chaleur, surtout en présence de lumière directe ou d’un éclairage interne puissant.

Conséquences :

- Surcharge du système de refroidissement de cave à vin

- Températures instables au-dessus de 13 °C

- Usure prématurée du compresseur

Solutions recommandées :

- Vitrage haute performance (triple vitrage ou vitrage sous vide) pour atteindre R-5 et plus

- Films Low-E et anti-UV pour limiter le gain solaire

- Éviter les murs orientés sud/ouest ou intégrer des protections solaires extérieures

- Utiliser des châssis à rupture thermique

- Associer un APEX 3500 ou 5000 Panthaire pour moduler la puissance et éviter le surrefroidissement.

2 – Mauvais calcul de la capacité de refroidissement (BTU)

Problème :

Un cellier en verre peut nécessiter 2 à 4 fois plus de BTU qu’un cellier isolé classique.

Solutions recommandées :

- Calculer la charge thermique avec un outil qui tient compte du pourcentage de vitrage, de l’exposition et de l’éclairage

- Ajouter une marge de 25 à 40 % si le vitrage dépasse 50 % des surfaces

- Choisir le modèle adapté :

- APEX 3500 : ≤ 900 pi³ (~3 350 BTU/h)

- APEX 5000 : 900–1 200 pi³ (~4 460 BTU/h)

- APEX 7000 : ≤ 2 000 pi³ (~6 350 BTU/h)

3 – Pare-vapeur mal exécuté

Problème :

Les infiltrations d’air chaud créent de la condensation dans la cave.

Solutions recommandées :

- Installer un pare-vapeur en polyéthylène 6 mil continu côté chaud (murs, plafond, plancher)

- Sceller les rails et joints avec un silicone sans dégazage nocif

- Utiliser le bac à condensats et l’auto-évaporation intégrés aux systèmes APEX

4 – Ventilation et circulation d’air mal conçues

Problème :

Les caves vitrées peuvent présenter des zones chaudes en hauteur et un manque de renouvellement d’air.

Solutions recommandées :

- Utiliser un conduit d’alimentation d’air et un conduit de retour d’air pour assurer 2–4 renouvellements/heure

- Placer l’alimentation près du sol et le retour près du plafond pour homogénéiser la température

- Maintenir un dégagement derrière les casiers pour favoriser le balayage d’air

- Profiter du flux adaptatif des APEX pour réduire l’écart vertical < 1 °C

5 – Oublier l’accès pour l’entretien

Problème :

Un accès insuffisant complique l’entretien et augmente les coûts de maintenance.

Solutions recommandées :

- Laisser 450 mm de dégagement devant le panneau de commande et le serpentin

- Prévoir des trappes ou panneaux d’accès démontables

- Étiqueter et positionner clairement les coupe-circuits

FAQ – Refroidissement des celliers vitrés

Faut-il surdimensionner l’appareil ? Oui, en raison de la faible isolation du verre.

Température idéale ? 12–14 °C toute l’année.

Pare-vapeur DIY ? Recommandé de confier à un professionnel.

Fréquence d’entretien ? Annuel, avec filtre, serpentin et bac à condensats.

Conclusion

Pour garantir la stabilité thermique et hygrométrique de votre cellier en verre haut de gamme, adoptez une approche globale : vitrage performant, système APEX Panthaire dimensionné avec précision, pare-vapeur professionnel, circulation d’air équilibrée et accès facile à l’entretien.

Les modèles APEX 3500, 5000 et 7000 sont conçus pour relever ces défis, assurant un refroidissement silencieux, un design invisible et une performance durable.