May 16, 2025

Cooling Glass Wine Cellars: 5 Design Mistakes to Avoid with Panthaire APEX

Discover the 5 most common mistakes when cooling a glass wine cellar and how Panthaire APEX 3500, 5000, and 7000 ducted systems deliver silent, precise temperature and humidity control for showcase collections.

Introduction

Glass-enclosed wine cellars have become a symbol of modern design and sophistication. However, cooling a glass wine room is far more complex than conditioning a traditional insulated cellar. Glass has a significantly lower R-value (~R-2) than an insulated wall (~R-20), which greatly increases thermal loads. Without careful planning — insulation, vapor barrier, BTU sizing, and controlled airflow — your wines risk exposure to temperature swings and excess humidity.

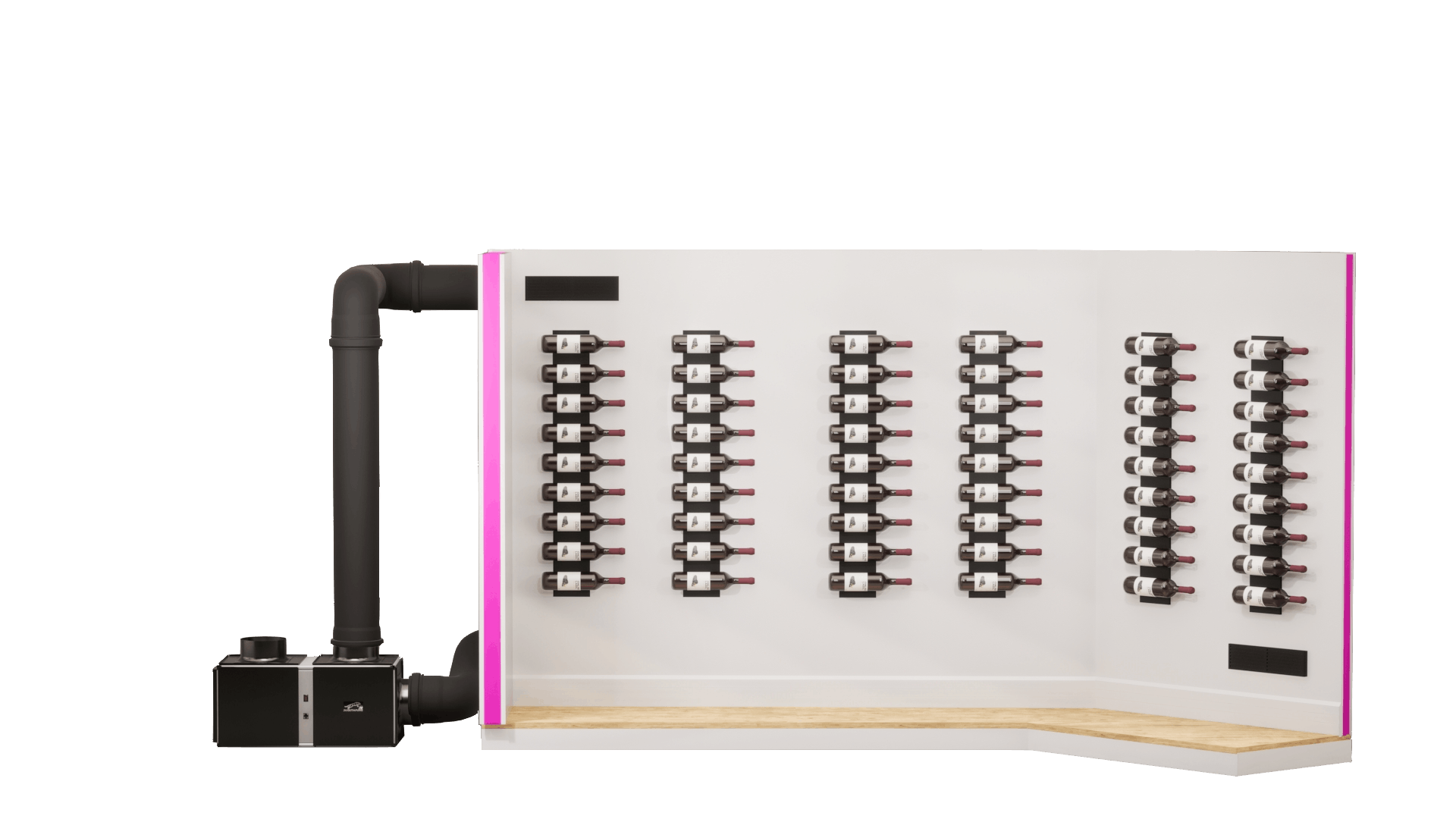

APEX Panthaire systems, designed and optimized for glass wine rooms, feature:

- Fully ducted operation (supply air duct + return air duct)

- Variable-speed ECM fans

- Integrated condensate management with stainless steel drain pan and auto-evaporation module

- Power output adapted to the high thermal loads of glass

1 – Insufficient thermal insulation for glass walls

Problem:

Standard glazing allows significant heat gain, especially with direct sunlight or strong internal lighting.

Consequences:

- Overload of the wine cellar cooling system

- Unstable temperatures above 55 °F (13 °C)

- Premature compressor wear

Recommended solutions:

- High-performance glazing (triple-pane or vacuum-insulated) to achieve R-5 or higher

- Low-E and UV-protection films to limit solar gain

- Avoid south-/west-facing walls or integrate exterior shading

- Use thermally broken frames

- Pair with a Panthaire APEX 3500 or 5000 to modulate power and prevent overcooling

2 – Incorrect cooling capacity (BTU) calculation

Problem:

A glass wine room can require 2 to 4 times more BTUs than a traditional insulated cellar.

Recommended solutions:

- Calculate heat load using a tool that factors glazing percentage, exposure, and lighting

- Add a 25–40% capacity margin if glazing exceeds 50% of the surfaces

- Select the right model:

- APEX 3500 — ≤ 900 cu ft (~3,350 BTU/h)

- APEX 5000 — 900–1,200 cu ft (~4,460 BTU/h)

- APEX 7000 — ≤ 2,000 cu ft (~6,350 BTU/h)

3 – Poor vapor barrier execution

Problem:

Warm air infiltration leads to condensation inside the cellar.

Recommended solutions:

- Install a continuous 6 mil polyethylene vapor barrier on the warm side (walls, ceiling, floor)

- Seal tracks and joints with non-off-gassing silicone

- Utilize the integrated drain pan and auto-evaporation system in APEX units

4 – Poorly designed ventilation and airflow

Problem:

Glass cellars can develop hot spots at the top and lack proper air turnover.

Recommended solutions:

- Use a supply air duct and return air duct to ensure 2–4 air changes per hour

- Place the supply near the floor and the return near the ceiling for balanced temperature

- Maintain clearance behind wine racks to allow proper air sweep

- Leverage APEX adaptive airflow to keep vertical temperature differences under 1 °C

5 – Overlooking maintenance access

Problem:

Insufficient access complicates maintenance and increases service costs.

Recommended solutions:

- Maintain at least 18 in (450 mm) clearance in front of the coil and control panel

- Provide removable or hinged access panels

- Clearly label and position electrical disconnects

FAQ – Cooling glass wine cellars

Should I oversize the unit? Yes, due to glass’s low insulation value.

Ideal temperature? 54–57 °F (12–14 °C) year-round.

DIY vapor barrier? Professional installation is recommended.

Maintenance frequency? Annually, with filter, coil, and drain pan service.

Conclusion

To ensure thermal and humidity stability in your high-end glass wine cellar, adopt a comprehensive approach: performance glazing, precisely sized APEX Panthaire system, professionally installed vapor barrier, balanced airflow, and easy maintenance access.

The APEX 3500, 5000, and 7000 are engineered to meet these challenges, delivering silent cooling, an invisible design, and lasting performance.